Why Upgrade?

The stock hot end on the Ender 3 is simple and capable, but the range of materials that can be used with it is minimal. That’s where all-metal hot ends come to the rescue.

Why Go All-Metal?

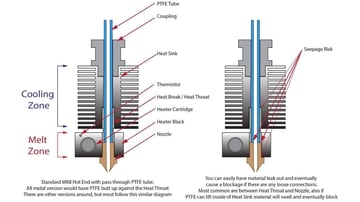

In a standard hot end, a PTFE tube is present all the way down the nozzle against the heat block. Because this PTFE tube starts degrading at temperatures over 250 °C, the range of materials that can be used is limited. After all, this PTFE tube emits toxic fumes and will need a replacement if used for an extended period at such high temperatures.

In an all-metal hot end, the PTFE tube is not inserted all the way down but instead sits on the top of the heat break. This allows you to print exotic and high-temperature materials like nylon, carbon fiber, and polycarbonate. This is the primary reason people upgrade to this type of hot end.

Pros and Cons

Now that we have some idea about what an all-metal hot end is, let’s discuss using it on your Ender 3.

Benefits:

- Higher temperatures: If you’re going to be printing with exotic or non-standard filaments, as mentioned earlier, an all-metal hot end is a must since they typically require high printing temperatures.

- No need for PTFE replacement: The PTFE tube will degrade over time when used for high-temperature printing with PETG and ABS. With an all-metal hot end, you won’t have to deal with replacing the PTFE liner at all.

Drawbacks:

-

Retraction settings: High-temperature filament tends to stick to the wall of the heat break if retracted too much. Hence, you should be starting with lower retraction settings when upgrading.

- For starters, lower the retraction distance to 3.5–4 mm and lower speeds to 45 mm/s. Make sure to experiment to find the best settings for your specific materials and hardware.

-

Clogging: In the heatsink, the filament is subjected to a drastic temperature difference. The heat break conducts heat much faster in the absence of a PTFE tube. If there’s any heat creep from the heat block, the filament might melt partially in the heat break itself. As the heatsink is being actively cooled, this partially-molten filament will solidify, resulting in a clog.

- Retraction settings also play a significant role in reducing clogs.

- To get the best temperature transition in the hot end, it is necessary for the heatsink to be actively and sufficiently cooled.

What's On the Market

Among the pool of hot ends that exist today, clones and original alike, these are some of the best ones that suit the Ender 3. High quality and precision manufacturing ensure the best printing performance for your high-temperature needs.

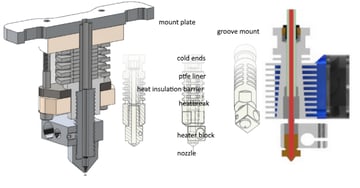

- Micro Swiss All-Metal Hot End: One of the best compatible hot ends for your Ender 3 is the Micro Swiss All-Metal Hot End. It fits perfectly without any need for extra brackets or mounts. The Micro Swiss uses a titanium heat break, which keeps the heat contained to the heat block only, and the nozzle is also plated with a wear-resistant coating. You can easily print abrasive materials such as carbon fiber and metal-filled filament without having to worry about nozzle wear.

- E3D V6: Undoubtedly the most versatile and popular design that exists on the market, the E3D V6 Hot End is famous for its reliability and material compatibility. It has a stainless steel heat break that keeps the PTFE away from the heating block. When mounting it on the Ender 3, there’s a small mount that needs to 3D printed, but then you’re all good to go.

- Mosquito Hot End: The newest product on this list is the Mosquito Hot End. It separates the heat break from the structural components, which results in much better thermal performance along with an improvement in printing quality. Although it’s an expensive option, it’s well worth the money spent. You will also need to 3D print a mount to fit your Mosquito Hot End on the Ender 3.

Closing Thoughts

The Ender 3 is one of the best budget 3D printers out there today, and upgrading it with an all-metal hot end would certainly enhance your printing experience. So why not make the jump and take your Ender 3 even further?

Feature image source: Ultimaker